As one of our core products, Parallel Twin Screw consists of a pair of precision-machined parallel screws and a pair of mutually perpendicular hollow shafts. Through its unique structural design, it achieves efficient mixing, conveying and processing of materials. Our Parallel Twin Screw products are complete in specifications and can meet the process requirements of different customers, thanks to our years of intensive cultivation in the field of plastic machinery and our deep understanding of market demand.

The materials used for Parallel Twin Screw have undergone a series of rigorous surface treatments to ensure the long life and high performance of the product. We use advanced double alloy spray welding technology to treat the surface of the screw. This technology has both high hardness and good wear resistance. By precisely controlling the spray welding parameters, the double alloy layer is closely combined with the base material to form a solid wear-resistant protective layer, which can resist the wear caused by the sliding of the material on the screw surface, and can also resist the erosion of harsh working conditions such as high temperature and corrosion, extending the service life of the screw. The application of this technology makes our Parallel Twin Screw more stable and reliable in the process of material mixing and conveying, improving production efficiency and product quality.

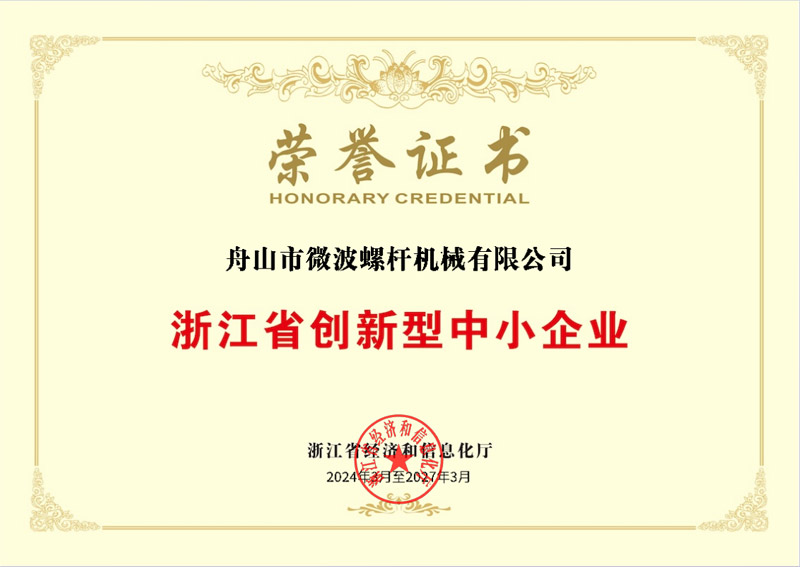

Zhoushan microwave screw machinery Co., LTD is a diversified large-scale professional production base. We produce Parallel Twin Screw, and also cover WB-WE series planetary screws, planetary barrels and planetary extruders; SJS series conical twin screws, twin barrels and twin screw plastic extruders; SJ series single screw, single barrel and single screw plastic extruders; pearl cotton screw barrels and various pipe, sheet and profile production lines. Parallel Twin Screw adopts a controllable tightening design to avoid the elastic deformation problem in the traditional screw transmission system and achieve higher precision motion control. This feature enables our products to maintain a stable operating state when subjected to large torque, and the optimized transmission efficiency reduces energy consumption, saving customers a lot of energy costs in the long-term use process and improving the sustainability of the overall operation.

Our Zhoushan microwave screw machinery Co., LTD has a professional R&D team and a complete after-sales service system, which can provide customers with full-process services from product design, production to installation and commissioning. The design of Parallel Twin Screw takes full account of torque bearing capacity and energy efficiency. The unique structure enables the screw to maintain a stable operating state when subjected to large torque, and the optimized transmission efficiency reduces energy consumption. This high-load and low-energy consumption feature improves the performance of Parallel Twin Screw and also reflects our company's unremitting pursuit of technological innovation and product optimization.

Our Parallel Twin Screw products are mainly exported to the United States, Germany, Dubai, Vietnam, Thailand and other countries or regions. We have established cooperative relations with many plastic production and construction machinery factory customers and have become their important supplier of mechanical parts in China. We always adhere to the principle of "reputation first, service first" and are committed to providing customers with high-quality products and services. Parallel Twin Screw has won the trust and praise of customers for its excellent performance and reliable quality. Customers from all walks of life are welcome to negotiate business and create a better future together.

English

English 中文簡體

中文簡體

浙公網(wǎng)安備33090202000520號

浙公網(wǎng)安備33090202000520號